Functions of Production Management - Meaning, PPT Video

1. Meaning of Function

1. Meaning of Function

The English word function originated from the Latin word ‘functionem’ and the French word ‘fonction’.[1] Here, the Latin word ‘functionem’ means to perform or execute a task, and the French word ‘fonction’ implies performing a role or serving a specific purpose.[2]

According to Merriam-Webster's Dictionary, the action for which a person or a thing is best suited is called function.[3]

According to the Collins Dictionary, a beneficial thing one does or intends to do is function.[4]

According to Oxford Learners Dictionaries, the function is a special or a particular activity done by any person or thing.[5]

Therefore, using the above explanations, we can say that a function is:

Image credits © Gaurav Akrani.

- A particular action,

- A special role,

- A beneficial thing,

- Serving a definite purpose or aim,

- Performed with a clear intention,

- Performed by a person or thing,

- Aimed at achieving a specific task or duty.

2. Meaning of Production

2. Meaning of Production

The English word ‘Production’ originated from the Latin verb ‘produco’ means to reveal something or bring it into existence for use.[6]

According to Merriam-Webster's Dictionary, a production is the act of producing something.[7]

According to the Collins Dictionary, production is the process of manufacturing goods in larger quantities.[8]

According to Oxford Learners Dictionaries, production means to make various goods and create materials for use.[9]

Therefore, using the above explanations, we can say that a production is:

Image credits © Gaurav Akrani.

- A process or an activity,

- A creation of utility,

- Bringing something into existence,

- Revealing something useful,

- An act of producing something,

- Manufacturing of goods,

- Creating goods or products in larger quantities,

- Making materials with utilities,

- Usually undertaken by companies and factories.

3. Meaning of Management

3. Meaning of Management

The English word Management originated from different words and has multiple origins. It emerged from the Latin word ‘manus’. Here, manus means a hand.[10] It also developed from the Italian verb ‘maneggiare’. Maneggiare means to handle something skillfully with proper care.[11] Management also originated from the French verb ‘mesnager’. Mesnager means a messenger or one who directs someone about something.[12]

According to the Cambridge Dictionary, “Controlling and organizing something is called management.” [13]

According to Fedmund Malik, “Management involves transforming resources into value, dealing with complexities, and controlling valuable systems.” [14] [15]

According to the expertise of Henri Fayol, “Management involves forecasting, planning, organizing, commanding, coordinating, and controlling something to achieve predefined goals or objectives.” [16]

According to Stanley C. Vance, author of Industrial Administration, “Management is a process that involves decision-making and controlling actions of humans to achieve goals.” [16] [17]

Thus, based on the above discussion, Management is:

Image credits © Gaurav Akrani.

- A systematic process,

- A decision-making process,

- A multi-level organ,

- A multi-purpose organ,

- To control and organize resources,

- To forecast and make a plan,

- To give commands and maintain coordination,

- To control the actions of humans,

- To transform resources into value,

- To simplify complexities and avoid confusion,

- Achieving targeted results, goals, or objectives,

- About performing effectively and managing efficiently.

4. Meaning of Production Management

4. Meaning of Production Management

Production Management refers to applying the Principles of Management to all production-related activities of a factory. It involves planning a production process, organizing essential resources (inputs) to initiate production, giving proper direction or guidance, and controlling its overall mechanism. It aims to produce quality goods or products in correct quantities using the right resources, technology, time, and human effort. It is also known as Manufacturing Management.[18] When a service-related factor gets added to its scope, it is called Operations Management.[19]

According to Edward Francis Leopold Brech, “Production Management is a process of effectively planning and regulating operations of the section (department) of an enterprise involved in transforming materials (inputs) into finished goods (outputs).” [20]

According to H. A. Harding, “Production Management is concerned only with those processes that convert (transform) valuable inputs like materials, men's labor, machinery or tools, methods or techniques, etc., into outputs like finished goods, quality products, and reliable services.” [21]

According to Elwood Spencer Buffa, “Production management is mainly involved in the decision-making of production processes. It aims to produce resulting goods or services according to fixed specifications, based on market demand, at a scheduled time, and incurring the minimum cost possible.” [22]

Thus, based on the above discussion, we can say, Production Management is:

Image credits © Gaurav Akrani.

- An application of management principles to production processes.

- To plan, organize, direct, and control all mechanisms of production.

- Aimed at producing the right quality and quantity of goods and services.

- Effective planning and regulation of all production operations.

- Concerned only with processes that convert inputs into outputs.

- Mainly a decision-making process about production processes.

5. Functions of Production Management

5. Functions of Production Management

The functions of production management are depicted and explained below.

The main components or functions of production management are as follows:

- Select the right product with a suitable design.

- Select an efficient production process.

- Maintain an optimal level of production capacity.

- Plan an effective production strategy.

- Monitor and control the production process.

- Maintain product quality and do cost control.

- Monitor and control the inventory stock.

- Maintain machines and replace outdated ones.

These functions of production management are discussed below in detail.

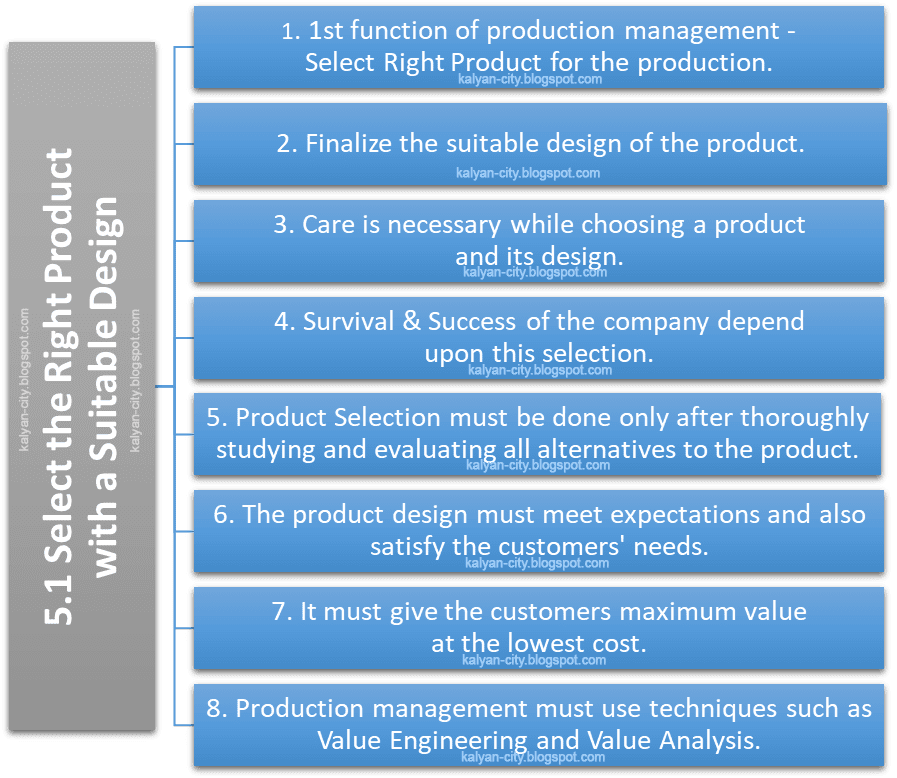

5.1 Select the Right Product with a Suitable Design

The crucial points on the selection and design of the product:

Image credits © Gaurav Akrani.

- The first function of production management is to select the right product for the production.

- Then, it moves ahead to finalize the suitable design of the product.

- Care is necessary while choosing a product and its design.

- The survival and success of the company depend upon this selection.

- The product selection must be done only after thoroughly studying and evaluating all alternatives to the product.

- The product design must meet expectations and also satisfy the customers' needs. It must give the customers maximum value at the lowest cost.

- Production management must use techniques such as Value Engineering and Value Analysis for Product Selection and Product Design.

5.2 Select an Efficient Production Process

The essential points on the selection of a production process:

Image credits © Gaurav Akrani.

- The second function of production management is to select an efficient and optimum production process.

- The materials used for production must be of good quality.

- The production process must use the latest technologies.

- The labor hired must be well-trained, experienced, and skilled.

- The new and efficient machines should take the place of outdated machinery.

- The material handling systems must function satisfactorily.

- There should be no wastage of materials utilized for production.

- The main focus should be on production quality and efficiency.

- The production process must be well-optimized to enhance the quality and output of the production. It will also help to avoid unnecessary losses and minimize overall input costs.

5.3 Maintain Optimal Level of Production Capacity

The vital points for maintaining the production capacity are:

Image credits © Gaurav Akrani.

- The third function of production management is to maintain an optimal level of production capacity.

- Production capacity is the maximum output a production may deliver when it functions at its optimum level.

- Production capacity must match the market demand for the product.

- It must be neither too low nor too high.

- It must be well-balanced to match up with the changing demand.

- If it is not balanced, it may create problems for the company.

- The production manager plays a crucial role in balancing production capacity.

- The production manager checks that production is neither too high nor too low.

- The production manager decides on long-term and short-term production.

- The production manager must use break-even analysis to find the optimum level of production capacity.

5.4 Plan an Effective Production Strategy

Ten crucial points to crave out an effective production strategy:

Image credits © Gaurav Akrani.

- The fourth function of production management is to plan an effective or result-oriented production strategy that works.

- Production strategy must be capable of seeking the targeted production goals and objectives at a pre-determined time.

- The targeted production goals are impossible to accomplish without a planned strategy.

- The production manager must decide about routing and scheduling.

- Routing means deciding the working path and sequence of operations in the manufacturing process.

- Routing finds the most economical and best-suited sequence of operations in the production process.

- Routing ensures the workflow remains smooth, functioning, and free from obstructions.

- Scheduling means to plan the beginning and end of a production-related activity.

- Scheduling decides when to start a production activity and when to complete or end it.

- The role of a production manager is indispensable in managing, maintaining, and operating the entire production process.

5.5 Monitor and control the production process

Essential details on monitoring and controlling the production process:

Image credits © Gaurav Akrani.

- The fifth function of production management is to monitor and control the entire production process.

- Monitoring involves observing and routinely checking whether production activity is going well as per expectation.[23]

- Controlling involves purposely restraining, adjusting, and influencing any sequence of a production operation.[24]

- The role of a production manager is to monitor and control the production process.

- The production manager must check production is carried out as per the production strategy.

- The production manager must be cautious and vigilant. He must prevent and not let the production course drift away from its targeted goals.

- The production manager must compare actual production with targeted production.

- The production manager must use his intelligence, knowledge, and experience to find deviations arising in the production process.

- The production manager must use his expertise and take all necessary steps to correct or fix such identified deviations.

- The monitoring and controlling help a production process run smoothly on a fixed track and prevent it from drifting away from its pre-determined path or goal.

5.6 Maintain product quality and do cost control

The main points to maintain product quality and control costs:

Image credits © Gaurav Akrani.

- The sixth function of production management is to maintain the product quality and control costs incurred to make a product.

- The product quality must be reliable and functional. It should satisfy consumers' expectations and their needs.

- The cost incurred to make a product should not be excessive and uncontrolled. Neither should it be low nor should it fall deficit.

- The manufacturing of a product must be at a reasonable cost without compromising quality, reliability, and functionality.

- The cost incurred in making a product should be profitable to a manufacturer and also affordable to consumers.

- Product quality and cost control are inseparable and are essential to succeed in today's cut-throat market competition.

- Today's consumers expect good-quality products at cheaper prices. Those who satisfy this expectation dominate the market.

- The production manager must consistently try his best to enhance the quality and reduce the costs of his products.

5.7 Monitor and control the inventory stock

Guidelines to monitor and control the inventory stock in production:

Image credits © Gaurav Akrani.

- The seventh function of production management is to monitor and control the inventory stock.

- Inventory includes raw materials, semi-finished goods, and other finished parts used to manufacture a product.[25]

- Inventory Stock is the inventory in possession kept safely in a warehouse to satisfy production needs.

- Production is not possible without maintaining a sufficient stock of inventory.

- The production manager must regularly monitor the level or stock of inventories.

- There should be neither understocking nor overstocking of inventories.

- If there is understocking, production will not start on time and will hurt deliveries.

- If there is overstocking, working capital is blocked, and materials may get spoiled, wasted, or misused.

- The best approach is to maintain a well-balanced and flexible stock of inventories at any time to fulfill and satisfy all dynamic production needs.

5.8 Maintain machines & replace outdated ones

Important points regarding machines used in the production process:

Image credits © Gaurav Akrani.

- The eighth function of production management is to maintain machines and replace those that have become obsolete.

- Machines are devices with a systematic arrangement designed to perform a particular task or work.

- Machines automate and speed up production processes. They save precious time and human energy.

- Without machines, the production process won't be able to keep pace with the rising market demands.

- Machines have directly and indirectly revolutionized the entire production process.

- If machines break down, production ceases, and the supply of products halts.

- A continuous production process is possible only if machines are maintained and replaced after they become obsolete.

- Machines often undergo wearing and tearing. Therefore, they need regular maintenance and servicing.

- The production manager must regularly check all machines are operating fine and undergo scheduled maintenance and servicing.

- Machines that are not maintainable or are obsolete should be removed and replaced by newer modern machines.

So these were eight significant functions of production management performed under the guidance and expertise of a production manager in the production process.

The following YouTube video presents the functions of production management.

Video credits © Gaurav Akrani.

6. References

6. References

The references used to compile and edit this article are listed as follows:

- ^ "Etymonline - Etymology of function". Retrieved 10 December 2024.

- ^ "Collins Dictionary - English Translation of FONCTION". Retrieved 10 December 2024.

- ^ "Merriam Webster - Meaning of Function". Retrieved 10 December 2024.

- ^ "Collins Dictionary - Definition and Meaning of Function". Retrieved 10 December 2024.

- ^ "Oxford Learners Dictionaries - Meaning of Function". Retrieved 10 December 2024.

- ^ "Cooljugator - Etymology of Production". Retrieved 10 December 2024.

- ^ "Merriam Webster - Definition and Meaning of Production". Retrieved 10 December 2024.

- ^ "Collins Dictionary - Definition and Meaning of Production". Retrieved 10 December 2024.

- ^ "Oxford Learners Dictionaries - Meaning of Production". Retrieved 11 December 2024.

- ^ "Cambridge Dictionary - English Meaning of Manus". Retrieved 11 December 2024.

- ^ "Collins Dictionary - English Translation of Italian Word Maneggiare". Retrieved 11 December 2024.

- ^ "Management Today - Meaning of Management". Retrieved 11 December 2024.

- ^ "Cambridge Dictionary - Meaning of Management". Retrieved 11 December 2024.

- ^ "Fredmund Malik's Profile". Retrieved 11 December 2024.

- ^ "Fredmund Malik - Management - The Essence of the Craft". Retrieved 11 December 2024.

- ^ "UGC Self-Learning - Unit 1 - Introduction to Management". Retrieved 11 December 2024.

- ^ "Stanley C. Vance - Industrial Administration". Retrieved 11 December 2024.

- ^ "Dr. Sudhakar Jadhavar - Production and Operation Management - Reference Book". Retrieved 11 December 2024.

- ^ "Rajeev Bansal - SBPD - Production Management". Retrieved 11 December 2024.

- ^ "Edward Francis Leopold - Organisation - The Framework of Management". Retrieved 11 December 2024.

- ^ "H. A. Harding - Production Management". Retrieved 11 December 2024.

- ^ " Elwood Buffa and Rakesh Sarin - Modern Production or Operations Management". Retrieved 11 December 2024.

- ^ "Vocabulory.com - Meaning of Monitor". Retrieved 12 December 2024.

- ^ "Merriam Webster - Definition and Meaning of Control". Retrieved 12 December 2024.

- ^ "Investopedia - What is Inventory?". Retrieved 12 December 2024.

This informative article was re-written, comprehensively edited, expanded, and updated by Gaurav Akrani on 16th December 2024.

-

Anonymous

said...

June 22, 2016 at 5:30 AMProduction is so important to students especially the manager: engineers and skilled workers..